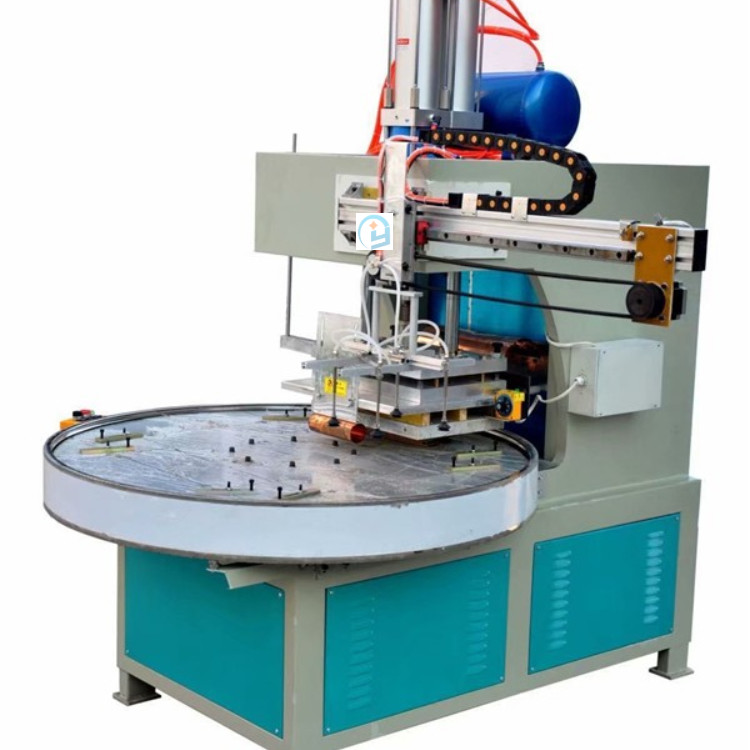

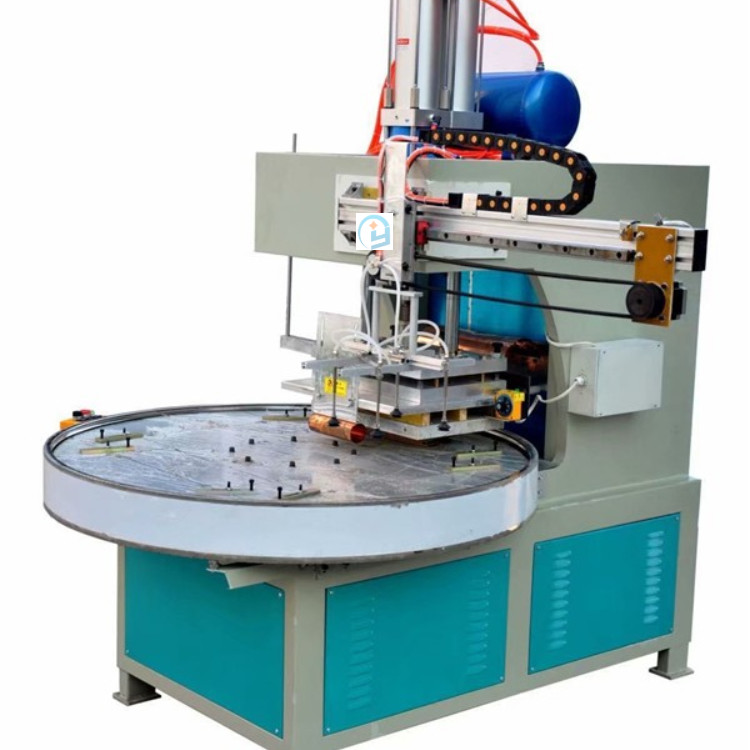

Title: 10 Reasons to Choose a High Frequency PVC Tarpaulin Welding Machine

Introduction

Introduction

In the world of industrial equipment, the high-frequency PVC tarpaulin welding machine stands out as a crucial tool for many businesses. From creating durable tarpaulins for outdoor use to manufacturing waterproof covers, this machine offers a wide range of benefits. In this article, we will explore 10 reasons why businesses should consider investing in a high-frequency PVC tarpaulin welding machine.

1. Increased Efficiency

One of the primary advantages of using a high-frequency PVC tarpaulin welding machine is the increased efficiency it offers. With the ability to weld materials together quickly and seamlessly, businesses can save time and resources on production.

In the world of industrial equipment, the high-frequency PVC tarpaulin welding machine stands out as a crucial tool for many businesses. From creating durable tarpaulins for outdoor use to manufacturing waterproof covers, this machine offers a wide range of benefits. In this article, we will explore 10 reasons why businesses should consider investing in a high-frequency PVC tarpaulin welding machine.

1. Increased Efficiency

One of the primary advantages of using a high-frequency PVC tarpaulin welding machine is the increased efficiency it offers. With the ability to weld materials together quickly and seamlessly, businesses can save time and resources on production.

2. Superior Strength

High-frequency PVC tarpaulin welding machines are known for producing welded seams that are incredibly strong and durable. This ensures that the finished products can withstand harsh weather conditions and heavy use without falling apart.

2. Superior Strength

High-frequency PVC tarpaulin welding machines are known for producing welded seams that are incredibly strong and durable. This ensures that the finished products can withstand harsh weather conditions and heavy use without falling apart.

3. Versatility

3. Versatility

From creating customized tarpaulins to manufacturing inflatable products, high-frequency PVC tarpaulin welding machines can handle a wide range of applications. This versatility allows businesses to expand their product offerings and cater to a diverse customer base.

4. Precision Welding

From creating customized tarpaulins to manufacturing inflatable products, high-frequency PVC tarpaulin welding machines can handle a wide range of applications. This versatility allows businesses to expand their product offerings and cater to a diverse customer base.

4. Precision Welding

The high-frequency technology used in these welding machines allows for precise and consistent welding results. This means that businesses can produce high-quality products with minimal margin for error.

5. Cost-Effective

While the initial investment in a high-frequency PVC tarpaulin welding machine may seem significant, businesses can save money in the long run by reducing labor costs and improving efficiency. The durability of the welded seams also means that products have a longer lifespan, further saving on replacement and repair costs.

The high-frequency technology used in these welding machines allows for precise and consistent welding results. This means that businesses can produce high-quality products with minimal margin for error.

5. Cost-Effective

While the initial investment in a high-frequency PVC tarpaulin welding machine may seem significant, businesses can save money in the long run by reducing labor costs and improving efficiency. The durability of the welded seams also means that products have a longer lifespan, further saving on replacement and repair costs.

6. User-Friendly Operation

6. User-Friendly Operation

Despite their advanced technology, high-frequency PVC tarpaulin welding machines are designed to be user-friendly. With intuitive controls and easy setup procedures, operators can quickly learn how to use the machine effectively.

Despite their advanced technology, high-frequency PVC tarpaulin welding machines are designed to be user-friendly. With intuitive controls and easy setup procedures, operators can quickly learn how to use the machine effectively.

7. Environmentally Friendly

Compared to traditional sewing methods, high-frequency PVC tarpaulin welding machines produce less waste and consume fewer resources. This makes them a more environmentally friendly option for businesses looking to reduce their carbon footprint.

8. Consistent Results

7. Environmentally Friendly

Compared to traditional sewing methods, high-frequency PVC tarpaulin welding machines produce less waste and consume fewer resources. This makes them a more environmentally friendly option for businesses looking to reduce their carbon footprint.

8. Consistent Results

Whether producing a small batch of products or mass-producing tarpaulins, high-frequency PVC tarpaulin welding machines deliver consistent results every time. Businesses can rely on the machine to maintain quality standards and meet customer expectations.

Whether producing a small batch of products or mass-producing tarpaulins, high-frequency PVC tarpaulin welding machines deliver consistent results every time. Businesses can rely on the machine to maintain quality standards and meet customer expectations.

9. Faster Production

With the ability to weld materials in a matter of seconds, high-frequency PVC tarpaulin welding machines enable businesses to ramp up their production speed. This is especially beneficial for meeting tight deadlines and fulfilling large orders.

10. Industry-Leading Technology

High-frequency PVC tarpaulin welding machines incorporate the latest technological advancements in the field of welding. By investing in one of these machines, businesses can stay ahead of the competition and ensure that their products meet industry standards.

9. Faster Production

With the ability to weld materials in a matter of seconds, high-frequency PVC tarpaulin welding machines enable businesses to ramp up their production speed. This is especially beneficial for meeting tight deadlines and fulfilling large orders.

10. Industry-Leading Technology

High-frequency PVC tarpaulin welding machines incorporate the latest technological advancements in the field of welding. By investing in one of these machines, businesses can stay ahead of the competition and ensure that their products meet industry standards.

Conclusion

In a world where quality and efficiency are paramount, a high-frequency PVC tarpaulin welding machine is a valuable asset for any business. From its superior strength to its versatility and precision welding capabilities, this machine offers a wide range of benefits. As Sheldon Cooper from “The Big Bang Theory” once said, “Well, the high frequency oscillation of the carbon dioxide laser beam creates an antibonding effect that weakens the molecular structure.” Similarly, the high-frequency technology of a PVC tarpaulin welding machine creates strong bonds that hold products together. Businesses that invest in this technology will undoubtedly reap the rewards in terms of increased efficiency, cost savings, and customer satisfaction.

Conclusion

In a world where quality and efficiency are paramount, a high-frequency PVC tarpaulin welding machine is a valuable asset for any business. From its superior strength to its versatility and precision welding capabilities, this machine offers a wide range of benefits. As Sheldon Cooper from “The Big Bang Theory” once said, “Well, the high frequency oscillation of the carbon dioxide laser beam creates an antibonding effect that weakens the molecular structure.” Similarly, the high-frequency technology of a PVC tarpaulin welding machine creates strong bonds that hold products together. Businesses that invest in this technology will undoubtedly reap the rewards in terms of increased efficiency, cost savings, and customer satisfaction.

Introduction

Introduction

In the world of industrial equipment, the high-frequency PVC tarpaulin welding machine stands out as a crucial tool for many businesses. From creating durable tarpaulins for outdoor use to manufacturing waterproof covers, this machine offers a wide range of benefits. In this article, we will explore 10 reasons why businesses should consider investing in a high-frequency PVC tarpaulin welding machine.

1. Increased Efficiency

One of the primary advantages of using a high-frequency PVC tarpaulin welding machine is the increased efficiency it offers. With the ability to weld materials together quickly and seamlessly, businesses can save time and resources on production.

In the world of industrial equipment, the high-frequency PVC tarpaulin welding machine stands out as a crucial tool for many businesses. From creating durable tarpaulins for outdoor use to manufacturing waterproof covers, this machine offers a wide range of benefits. In this article, we will explore 10 reasons why businesses should consider investing in a high-frequency PVC tarpaulin welding machine.

1. Increased Efficiency

One of the primary advantages of using a high-frequency PVC tarpaulin welding machine is the increased efficiency it offers. With the ability to weld materials together quickly and seamlessly, businesses can save time and resources on production.

2. Superior Strength

High-frequency PVC tarpaulin welding machines are known for producing welded seams that are incredibly strong and durable. This ensures that the finished products can withstand harsh weather conditions and heavy use without falling apart.

2. Superior Strength

High-frequency PVC tarpaulin welding machines are known for producing welded seams that are incredibly strong and durable. This ensures that the finished products can withstand harsh weather conditions and heavy use without falling apart.

3. Versatility

3. Versatility

From creating customized tarpaulins to manufacturing inflatable products, high-frequency PVC tarpaulin welding machines can handle a wide range of applications. This versatility allows businesses to expand their product offerings and cater to a diverse customer base.

4. Precision Welding

From creating customized tarpaulins to manufacturing inflatable products, high-frequency PVC tarpaulin welding machines can handle a wide range of applications. This versatility allows businesses to expand their product offerings and cater to a diverse customer base.

4. Precision Welding

The high-frequency technology used in these welding machines allows for precise and consistent welding results. This means that businesses can produce high-quality products with minimal margin for error.

5. Cost-Effective

While the initial investment in a high-frequency PVC tarpaulin welding machine may seem significant, businesses can save money in the long run by reducing labor costs and improving efficiency. The durability of the welded seams also means that products have a longer lifespan, further saving on replacement and repair costs.

The high-frequency technology used in these welding machines allows for precise and consistent welding results. This means that businesses can produce high-quality products with minimal margin for error.

5. Cost-Effective

While the initial investment in a high-frequency PVC tarpaulin welding machine may seem significant, businesses can save money in the long run by reducing labor costs and improving efficiency. The durability of the welded seams also means that products have a longer lifespan, further saving on replacement and repair costs.

6. User-Friendly Operation

6. User-Friendly Operation

Despite their advanced technology, high-frequency PVC tarpaulin welding machines are designed to be user-friendly. With intuitive controls and easy setup procedures, operators can quickly learn how to use the machine effectively.

Despite their advanced technology, high-frequency PVC tarpaulin welding machines are designed to be user-friendly. With intuitive controls and easy setup procedures, operators can quickly learn how to use the machine effectively.

7. Environmentally Friendly

Compared to traditional sewing methods, high-frequency PVC tarpaulin welding machines produce less waste and consume fewer resources. This makes them a more environmentally friendly option for businesses looking to reduce their carbon footprint.

8. Consistent Results

7. Environmentally Friendly

Compared to traditional sewing methods, high-frequency PVC tarpaulin welding machines produce less waste and consume fewer resources. This makes them a more environmentally friendly option for businesses looking to reduce their carbon footprint.

8. Consistent Results

Whether producing a small batch of products or mass-producing tarpaulins, high-frequency PVC tarpaulin welding machines deliver consistent results every time. Businesses can rely on the machine to maintain quality standards and meet customer expectations.

Whether producing a small batch of products or mass-producing tarpaulins, high-frequency PVC tarpaulin welding machines deliver consistent results every time. Businesses can rely on the machine to maintain quality standards and meet customer expectations.

9. Faster Production

With the ability to weld materials in a matter of seconds, high-frequency PVC tarpaulin welding machines enable businesses to ramp up their production speed. This is especially beneficial for meeting tight deadlines and fulfilling large orders.

10. Industry-Leading Technology

High-frequency PVC tarpaulin welding machines incorporate the latest technological advancements in the field of welding. By investing in one of these machines, businesses can stay ahead of the competition and ensure that their products meet industry standards.

9. Faster Production

With the ability to weld materials in a matter of seconds, high-frequency PVC tarpaulin welding machines enable businesses to ramp up their production speed. This is especially beneficial for meeting tight deadlines and fulfilling large orders.

10. Industry-Leading Technology

High-frequency PVC tarpaulin welding machines incorporate the latest technological advancements in the field of welding. By investing in one of these machines, businesses can stay ahead of the competition and ensure that their products meet industry standards.

Conclusion

In a world where quality and efficiency are paramount, a high-frequency PVC tarpaulin welding machine is a valuable asset for any business. From its superior strength to its versatility and precision welding capabilities, this machine offers a wide range of benefits. As Sheldon Cooper from “The Big Bang Theory” once said, “Well, the high frequency oscillation of the carbon dioxide laser beam creates an antibonding effect that weakens the molecular structure.” Similarly, the high-frequency technology of a PVC tarpaulin welding machine creates strong bonds that hold products together. Businesses that invest in this technology will undoubtedly reap the rewards in terms of increased efficiency, cost savings, and customer satisfaction.

Conclusion

In a world where quality and efficiency are paramount, a high-frequency PVC tarpaulin welding machine is a valuable asset for any business. From its superior strength to its versatility and precision welding capabilities, this machine offers a wide range of benefits. As Sheldon Cooper from “The Big Bang Theory” once said, “Well, the high frequency oscillation of the carbon dioxide laser beam creates an antibonding effect that weakens the molecular structure.” Similarly, the high-frequency technology of a PVC tarpaulin welding machine creates strong bonds that hold products together. Businesses that invest in this technology will undoubtedly reap the rewards in terms of increased efficiency, cost savings, and customer satisfaction.