Unlock the Secrets of High Frequency PVC Seal Machines: 10 Reasons to Choose from the Best

Introduction:

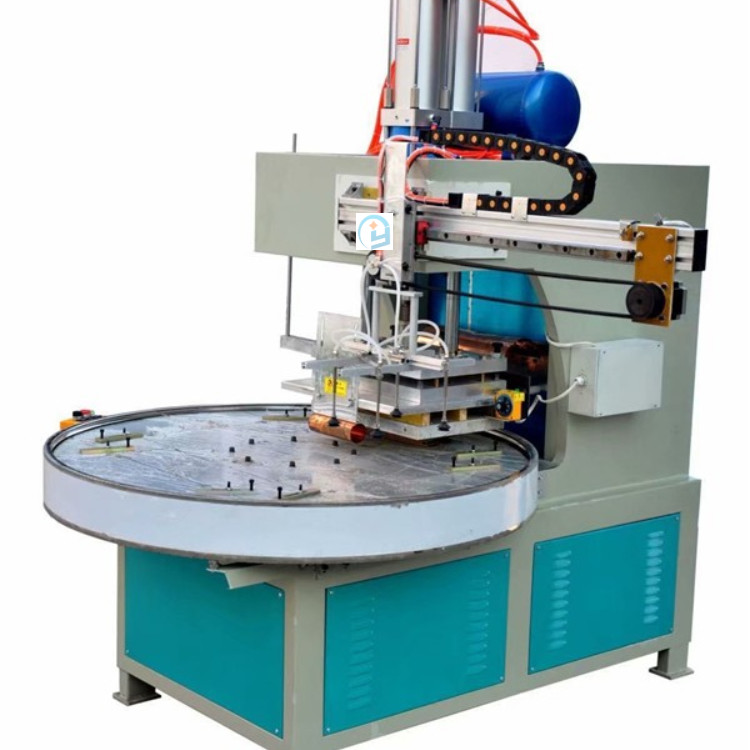

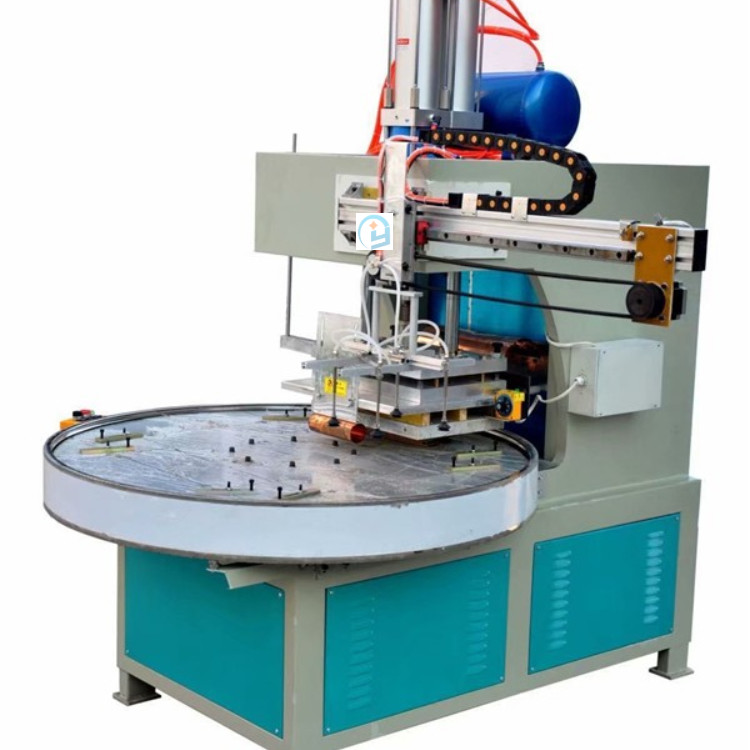

In the world of manufacturing, efficiency and precision are key. High frequency PVC seal machines have revolutionized the industry with their advanced technology and impressive capabilities. If you’re in the market for a new machine, here are 10 reasons why you should choose from the best high frequency PVC seal machines available.

Introduction:

In the world of manufacturing, efficiency and precision are key. High frequency PVC seal machines have revolutionized the industry with their advanced technology and impressive capabilities. If you’re in the market for a new machine, here are 10 reasons why you should choose from the best high frequency PVC seal machines available.

1. Superior Sealing Power:

1. Superior Sealing Power:

High frequency PVC seal machines are known for their superior sealing power. These machines use high-frequency electromagnetic waves to bond PVC materials together, creating strong and durable seals. This ensures that your products are securely sealed and protected from external elements.

Case Study: A company in the packaging industry switched to a high frequency PVC seal machine and saw a significant decrease in product defects due to improved sealing quality.

High frequency PVC seal machines are known for their superior sealing power. These machines use high-frequency electromagnetic waves to bond PVC materials together, creating strong and durable seals. This ensures that your products are securely sealed and protected from external elements.

Case Study: A company in the packaging industry switched to a high frequency PVC seal machine and saw a significant decrease in product defects due to improved sealing quality.

2. Versatility:

High frequency PVC seal machines are extremely versatile and can work with a wide range of materials, including PVC, PET, and PU. This versatility allows you to produce a variety of products with different material requirements without needing multiple machines.

2. Versatility:

High frequency PVC seal machines are extremely versatile and can work with a wide range of materials, including PVC, PET, and PU. This versatility allows you to produce a variety of products with different material requirements without needing multiple machines.

3. Efficiency:

3. Efficiency:

High frequency PVC seal machines are highly efficient, with fast cycle times and minimal downtime. This means that you can increase your production output and reduce lead times, leading to cost savings and improved customer satisfaction.

4. Precision:

High frequency PVC seal machines are highly efficient, with fast cycle times and minimal downtime. This means that you can increase your production output and reduce lead times, leading to cost savings and improved customer satisfaction.

4. Precision:

These machines offer precise control over the sealing process, ensuring consistent results every time. This level of precision is essential for industries that require tight tolerances and high-quality finishes.

5. User-Friendly Design:

These machines offer precise control over the sealing process, ensuring consistent results every time. This level of precision is essential for industries that require tight tolerances and high-quality finishes.

5. User-Friendly Design:

High frequency PVC seal machines are designed with user convenience in mind. They feature intuitive controls, easy setup procedures, and minimal maintenance requirements. This makes them easy to operate, even for operators with limited experience.

High frequency PVC seal machines are designed with user convenience in mind. They feature intuitive controls, easy setup procedures, and minimal maintenance requirements. This makes them easy to operate, even for operators with limited experience.

6. Cost-Effective:

6. Cost-Effective:

Investing in a high frequency PVC seal machine is a cost-effective choice in the long run. These machines have low operating costs and are built to last, reducing the need for frequent repairs or replacements.

7. Energy Efficiency:

High frequency PVC seal machines are energy-efficient, consuming less power than traditional sealing methods. This not only reduces your environmental impact but also helps lower your electricity bills.

Investing in a high frequency PVC seal machine is a cost-effective choice in the long run. These machines have low operating costs and are built to last, reducing the need for frequent repairs or replacements.

7. Energy Efficiency:

High frequency PVC seal machines are energy-efficient, consuming less power than traditional sealing methods. This not only reduces your environmental impact but also helps lower your electricity bills.

8. Safety Features:

Safety is always a top priority in manufacturing environments. High frequency PVC seal machines come equipped with advanced safety features, such as emergency stop buttons and safety sensors, to protect operators from accidents.

9. Space-Saving Design:

High frequency PVC seal machines are compact and space-saving, making them suitable for small manufacturing facilities with limited space. Their modular design allows for easy integration into existing production lines.

10. Future-Proof Technology:

8. Safety Features:

Safety is always a top priority in manufacturing environments. High frequency PVC seal machines come equipped with advanced safety features, such as emergency stop buttons and safety sensors, to protect operators from accidents.

9. Space-Saving Design:

High frequency PVC seal machines are compact and space-saving, making them suitable for small manufacturing facilities with limited space. Their modular design allows for easy integration into existing production lines.

10. Future-Proof Technology:

High frequency PVC seal machines are built with cutting-edge technology that is designed to meet the demands of tomorrow. By investing in a high-quality machine now, you can future-proof your manufacturing process and stay ahead of the competition.

Conclusion:

In conclusion, high frequency PVC seal machines offer a wide range of benefits that make them a top choice for manufacturers looking to improve their sealing processes. From superior sealing power to energy efficiency, these machines have it all. So why settle for anything less? Choose from the best high frequency PVC seal machines available and take your manufacturing operation to the next level!

“Everything is better with a little bit of high frequency PVC seal machine magic!” – Sheldon Cooper

High frequency PVC seal machines are built with cutting-edge technology that is designed to meet the demands of tomorrow. By investing in a high-quality machine now, you can future-proof your manufacturing process and stay ahead of the competition.

Conclusion:

In conclusion, high frequency PVC seal machines offer a wide range of benefits that make them a top choice for manufacturers looking to improve their sealing processes. From superior sealing power to energy efficiency, these machines have it all. So why settle for anything less? Choose from the best high frequency PVC seal machines available and take your manufacturing operation to the next level!

“Everything is better with a little bit of high frequency PVC seal machine magic!” – Sheldon Cooper

Introduction:

In the world of manufacturing, efficiency and precision are key. High frequency PVC seal machines have revolutionized the industry with their advanced technology and impressive capabilities. If you’re in the market for a new machine, here are 10 reasons why you should choose from the best high frequency PVC seal machines available.

Introduction:

In the world of manufacturing, efficiency and precision are key. High frequency PVC seal machines have revolutionized the industry with their advanced technology and impressive capabilities. If you’re in the market for a new machine, here are 10 reasons why you should choose from the best high frequency PVC seal machines available.

1. Superior Sealing Power:

1. Superior Sealing Power:

High frequency PVC seal machines are known for their superior sealing power. These machines use high-frequency electromagnetic waves to bond PVC materials together, creating strong and durable seals. This ensures that your products are securely sealed and protected from external elements.

Case Study: A company in the packaging industry switched to a high frequency PVC seal machine and saw a significant decrease in product defects due to improved sealing quality.

High frequency PVC seal machines are known for their superior sealing power. These machines use high-frequency electromagnetic waves to bond PVC materials together, creating strong and durable seals. This ensures that your products are securely sealed and protected from external elements.

Case Study: A company in the packaging industry switched to a high frequency PVC seal machine and saw a significant decrease in product defects due to improved sealing quality.

2. Versatility:

High frequency PVC seal machines are extremely versatile and can work with a wide range of materials, including PVC, PET, and PU. This versatility allows you to produce a variety of products with different material requirements without needing multiple machines.

2. Versatility:

High frequency PVC seal machines are extremely versatile and can work with a wide range of materials, including PVC, PET, and PU. This versatility allows you to produce a variety of products with different material requirements without needing multiple machines.

3. Efficiency:

3. Efficiency:

High frequency PVC seal machines are highly efficient, with fast cycle times and minimal downtime. This means that you can increase your production output and reduce lead times, leading to cost savings and improved customer satisfaction.

4. Precision:

High frequency PVC seal machines are highly efficient, with fast cycle times and minimal downtime. This means that you can increase your production output and reduce lead times, leading to cost savings and improved customer satisfaction.

4. Precision:

These machines offer precise control over the sealing process, ensuring consistent results every time. This level of precision is essential for industries that require tight tolerances and high-quality finishes.

5. User-Friendly Design:

These machines offer precise control over the sealing process, ensuring consistent results every time. This level of precision is essential for industries that require tight tolerances and high-quality finishes.

5. User-Friendly Design:

High frequency PVC seal machines are designed with user convenience in mind. They feature intuitive controls, easy setup procedures, and minimal maintenance requirements. This makes them easy to operate, even for operators with limited experience.

High frequency PVC seal machines are designed with user convenience in mind. They feature intuitive controls, easy setup procedures, and minimal maintenance requirements. This makes them easy to operate, even for operators with limited experience.

6. Cost-Effective:

6. Cost-Effective:

Investing in a high frequency PVC seal machine is a cost-effective choice in the long run. These machines have low operating costs and are built to last, reducing the need for frequent repairs or replacements.

7. Energy Efficiency:

High frequency PVC seal machines are energy-efficient, consuming less power than traditional sealing methods. This not only reduces your environmental impact but also helps lower your electricity bills.

Investing in a high frequency PVC seal machine is a cost-effective choice in the long run. These machines have low operating costs and are built to last, reducing the need for frequent repairs or replacements.

7. Energy Efficiency:

High frequency PVC seal machines are energy-efficient, consuming less power than traditional sealing methods. This not only reduces your environmental impact but also helps lower your electricity bills.

8. Safety Features:

Safety is always a top priority in manufacturing environments. High frequency PVC seal machines come equipped with advanced safety features, such as emergency stop buttons and safety sensors, to protect operators from accidents.

9. Space-Saving Design:

High frequency PVC seal machines are compact and space-saving, making them suitable for small manufacturing facilities with limited space. Their modular design allows for easy integration into existing production lines.

10. Future-Proof Technology:

8. Safety Features:

Safety is always a top priority in manufacturing environments. High frequency PVC seal machines come equipped with advanced safety features, such as emergency stop buttons and safety sensors, to protect operators from accidents.

9. Space-Saving Design:

High frequency PVC seal machines are compact and space-saving, making them suitable for small manufacturing facilities with limited space. Their modular design allows for easy integration into existing production lines.

10. Future-Proof Technology:

High frequency PVC seal machines are built with cutting-edge technology that is designed to meet the demands of tomorrow. By investing in a high-quality machine now, you can future-proof your manufacturing process and stay ahead of the competition.

Conclusion:

In conclusion, high frequency PVC seal machines offer a wide range of benefits that make them a top choice for manufacturers looking to improve their sealing processes. From superior sealing power to energy efficiency, these machines have it all. So why settle for anything less? Choose from the best high frequency PVC seal machines available and take your manufacturing operation to the next level!

“Everything is better with a little bit of high frequency PVC seal machine magic!” – Sheldon Cooper

High frequency PVC seal machines are built with cutting-edge technology that is designed to meet the demands of tomorrow. By investing in a high-quality machine now, you can future-proof your manufacturing process and stay ahead of the competition.

Conclusion:

In conclusion, high frequency PVC seal machines offer a wide range of benefits that make them a top choice for manufacturers looking to improve their sealing processes. From superior sealing power to energy efficiency, these machines have it all. So why settle for anything less? Choose from the best high frequency PVC seal machines available and take your manufacturing operation to the next level!

“Everything is better with a little bit of high frequency PVC seal machine magic!” – Sheldon Cooper