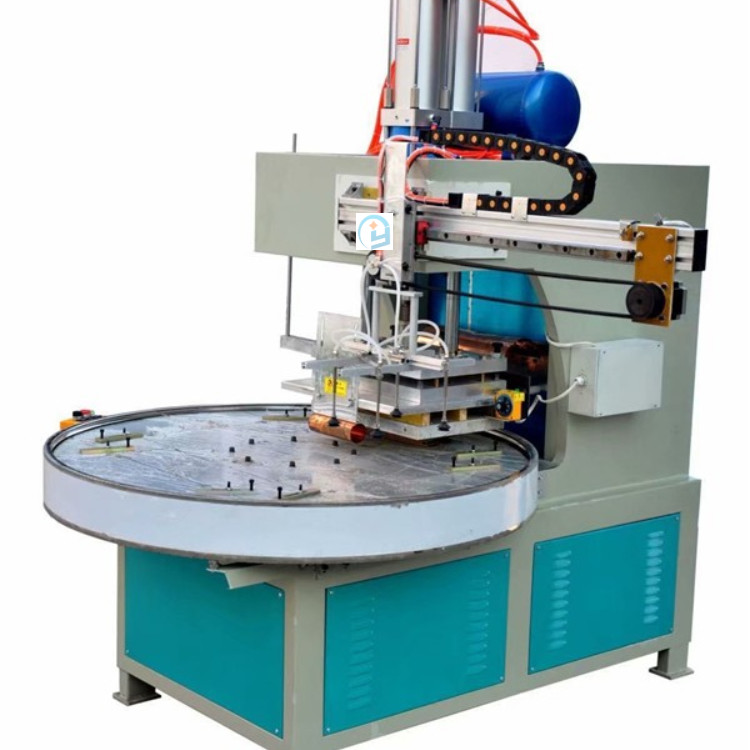

Introduction: In the world of manufacturing and production, having the right equipment can make all the difference. High frequency heat sealing machines are a versatile tool that offer a wide range of benefits for businesses looking to improve their processes. Here are 10 reasons why you should consider choosing a high frequency heat sealing machine.

1. Precision Sealing Capabilities

High frequency heat sealing machines use electromagnetic waves to create precise and consistent seals on various materials. This level of precision ensures that each product is sealed securely, reducing the risk of leaks or contamination.

2. Versatility in Material Usage

From PVC and PET to nylon and TPU, high frequency heat sealing machines can work with a wide range of materials. This versatility allows businesses to seal different types of products without having to invest in multiple machines.

3. Increased Production Efficiency

By automating the sealing process, high frequency heat sealing machines can significantly increase production efficiency. With faster sealing times and minimal setup requirements, businesses can save time and labor costs.

4. Cost-Effective Solution

Investing in a high frequency heat sealing machine can lead to long-term cost savings. By eliminating the need for manual sealing or outsourcing services, businesses can reduce operational expenses and increase profitability.

5. Consistent Seal Quality

Consistency is key in manufacturing, and high frequency heat sealing machines deliver uniform seal quality every time. This ensures that each product meets the required standards and maintains a professional appearance.

6. Enhanced Safety Features

With advanced safety features such as automatic shut-off and emergency stop buttons, high frequency heat sealing machines prioritize operator safety. This reduces the risk of accidents and creates a safe working environment for employees.

7. Environmental Sustainability

High frequency heat sealing machines produce minimal waste compared to other sealing methods. By using clean and efficient technology, businesses can contribute to environmental sustainability and reduce their carbon footprint.

8. Seamless Integration with Existing Equipment

Whether you have a small-scale operation or a large manufacturing facility, high frequency heat sealing machines can be easily integrated into your existing production line. This seamless integration ensures minimal disruption to your workflow.

9. Case Study: XYZ Company

XYZ Company, a leading manufacturer of medical devices, saw a 30% increase in production efficiency after implementing a high frequency heat sealing machine. The machine’s precision sealing capabilities and versatility in material usage allowed the company to meet tight deadlines and deliver high-quality products to their customers.

10. In conclusion, high frequency heat sealing machines offer a wide range of benefits for businesses looking to improve their production processes. From precision sealing capabilities to cost-effective solutions, these machines are a valuable investment for any manufacturing operation. As Sheldon Cooper from The Big Bang Theory would say, “I’m not crazy; my mother had me tested.” So, if you’re considering a high frequency heat sealing machine, rest assured that you’re making a smart choice for your business.