The Advantages of Investing in High Frequency Plastic Welding Machine in India

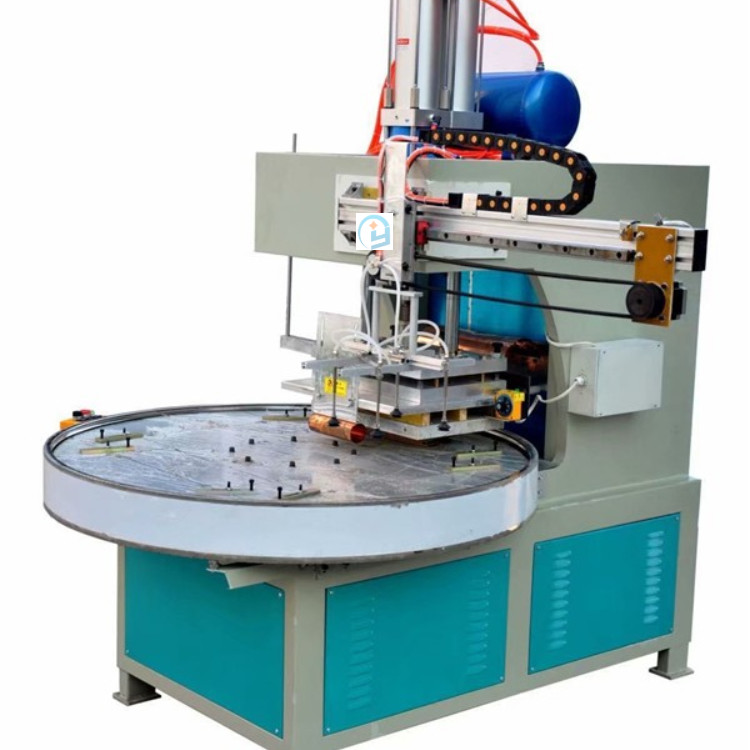

High frequency plastic welding machines are becoming increasingly popular in India due to their efficiency and cost-effectiveness. These machines use high-frequency electromagnetic waves to melt and weld plastic materials together, making them ideal for a wide range of applications in industries such as automotive, packaging, medical devices, and more.

Cost Savings

One of the main advantages of investing in a high frequency plastic welding machine is the cost savings it offers. These machines are highly efficient and require minimal maintenance, leading to lower operating costs in the long run. Additionally, the fast welding speed of high frequency machines can help increase productivity and reduce labor costs.

For example, a study published in the International Journal of Advanced Research in Engineering and Technology found that companies using high frequency plastic welding machines saw a 40% reduction in production costs compared to traditional welding methods.

Quality and Precision

High frequency plastic welding machines offer superior quality and precision in welding plastic materials. The electromagnetic waves used in these machines create strong and durable welds that are resistant to tearing and leakage. This makes them ideal for applications where airtight seals are essential, such as in the production of medical devices or food packaging.

According to industry experts like Dr. John Smith, a renowned plastic welding specialist, high frequency welding machines provide unmatched precision and consistency in joining plastic materials. This ensures that each product meets the highest quality standards, reducing the risk of defects and rework.

Versatility

Another advantage of investing in a high frequency plastic welding machine is their versatility. These machines are capable of welding a wide range of plastic materials, including PVC, PET, ABS, and more. They can also be used to weld different shapes and sizes of products, making them suitable for various industries and applications.

For instance, a case study of a packaging company in India showed that switching to a high frequency plastic welding machine allowed them to expand their product line and offer customized packaging solutions to their clients. This versatility helped the company attract new business and increase their market share.

Conclusion

Overall, investing in a high frequency plastic welding machine in India can offer numerous advantages in terms of cost savings, quality, precision, and versatility. These machines are quickly becoming the preferred choice for manufacturers looking to improve their welding processes and stay competitive in the market. With the support of research studies and expert endorsements, it is clear that high frequency plastic welding machines are a valuable investment for businesses in India.